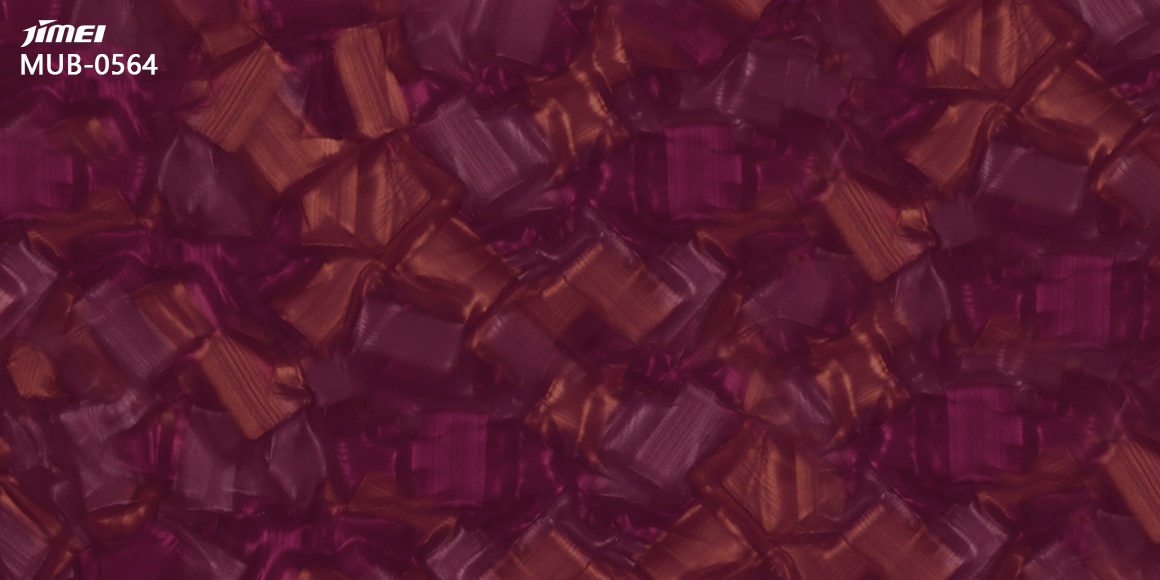

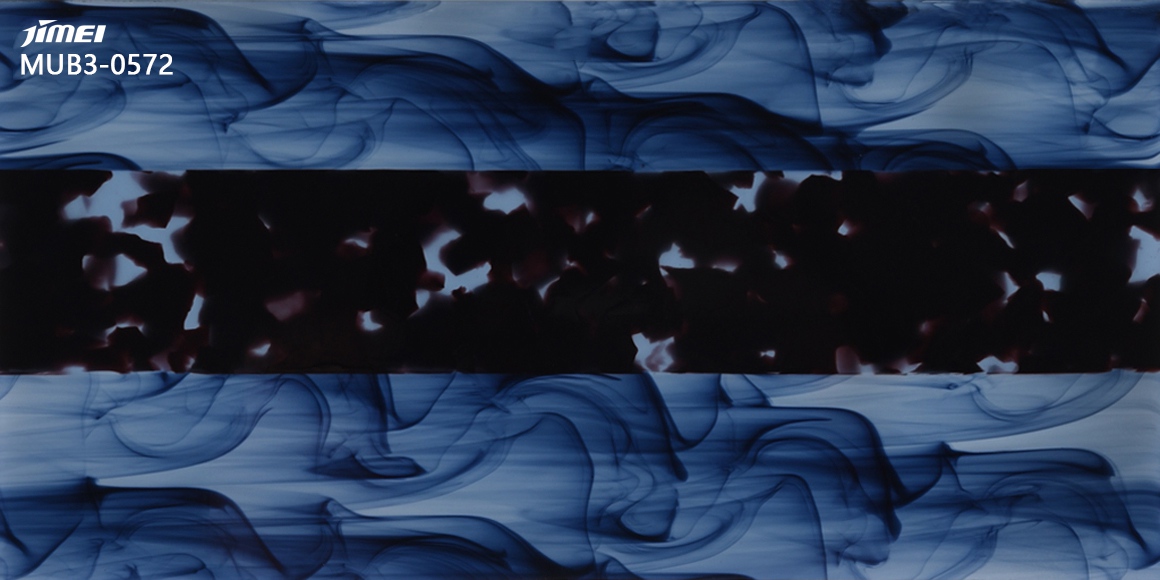

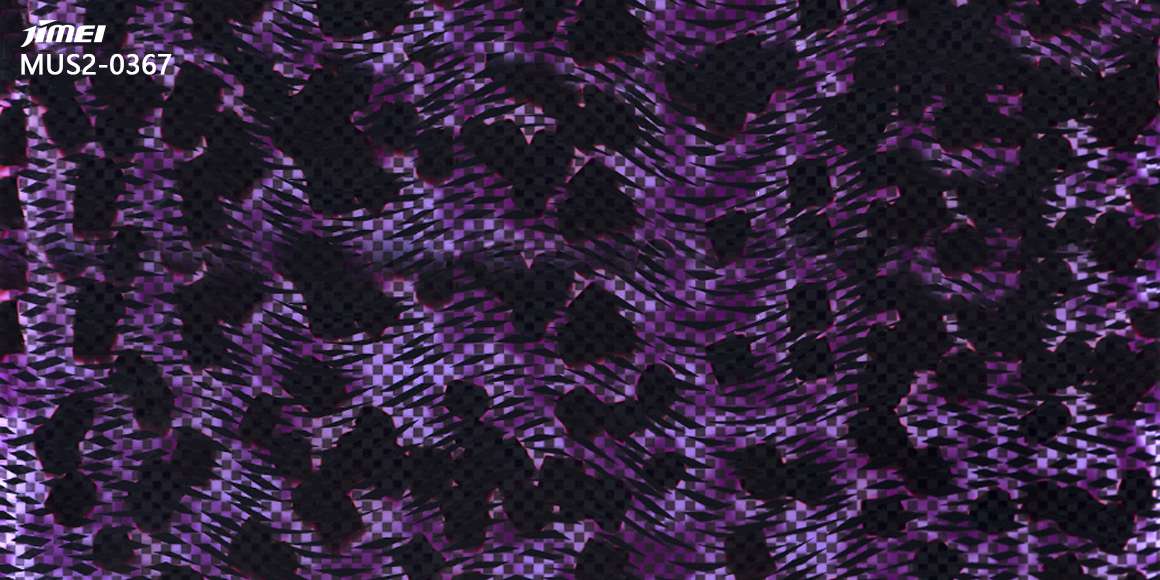

Our extruded acetate products undergo a meticulous process of color development, mixing, pelletizing, and extrusion. This results in materials with rich colors, excellent texture, and easy processability. Our main extruded collections include monocolor, multilayers, horn, and gradient. Different types of extruded acetate products achieve their unique structures and effects in distinct ways.

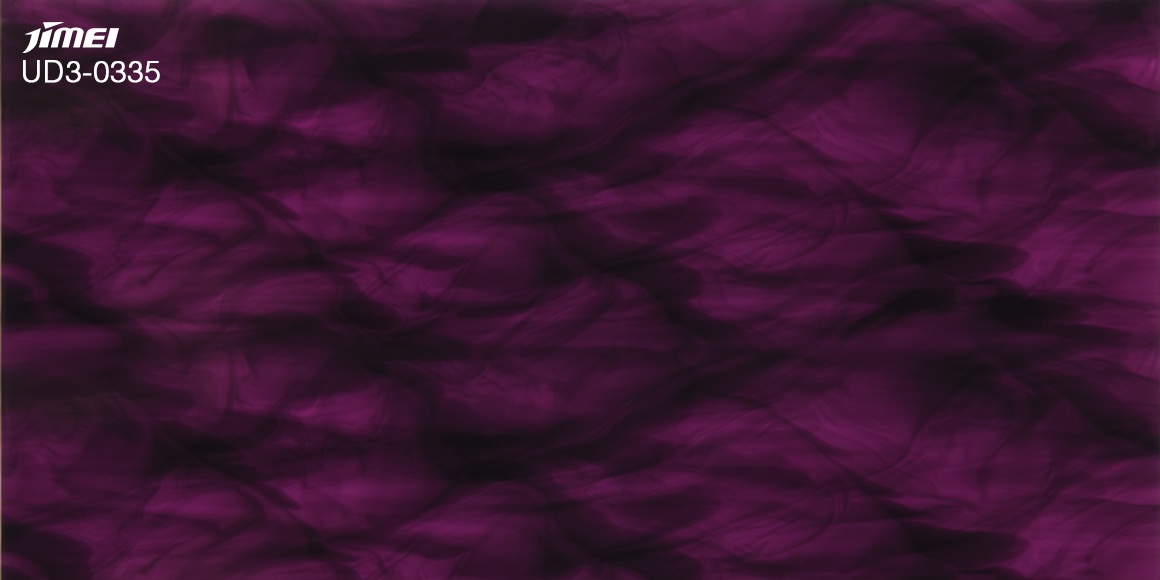

Monocolor can produce diverse effects, such as solid, milky, transparent, or pearl, by simply adjusting the color pigments.

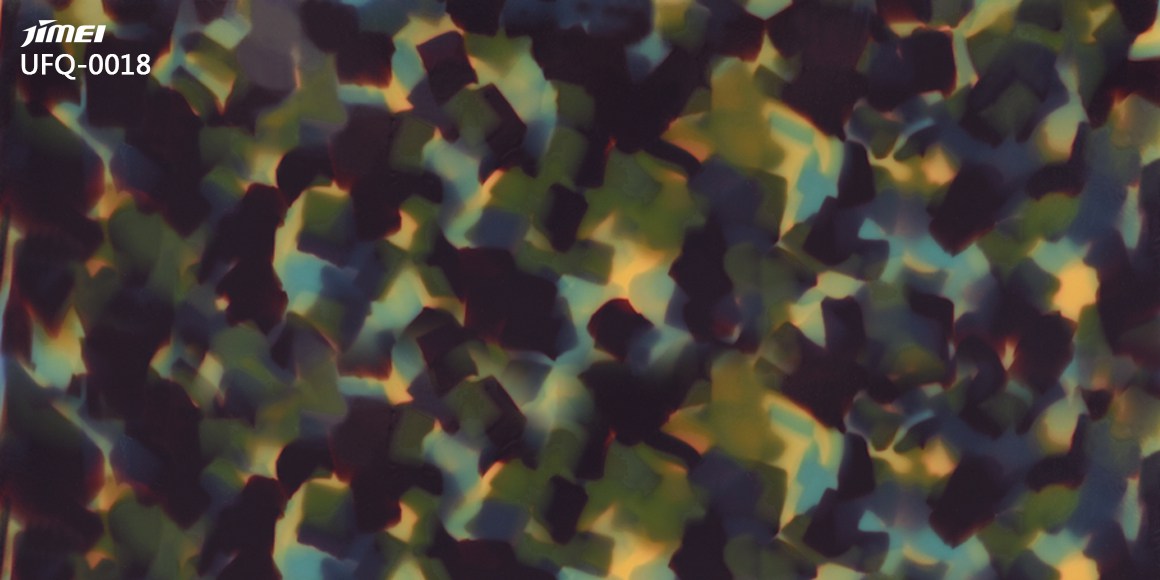

Multilayers create striking 2 to 5-layer effects by extruding different colors together, offering vibrant, well-defined hierarchies.

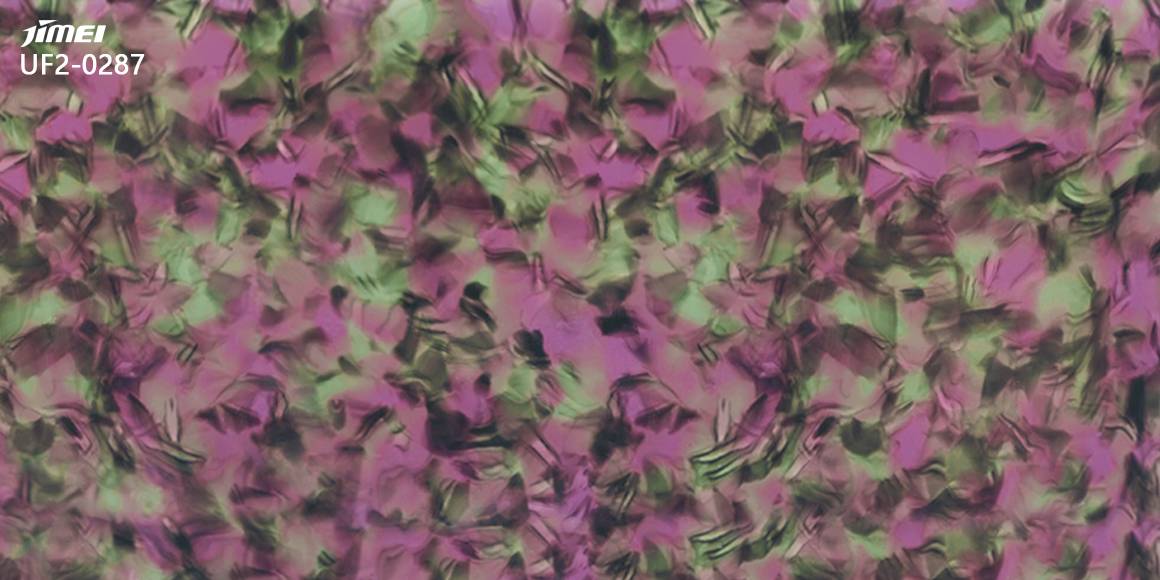

Horn can produce simple or colorful patterns and structures through the co-extrusion of various color combinations using specialized molds.

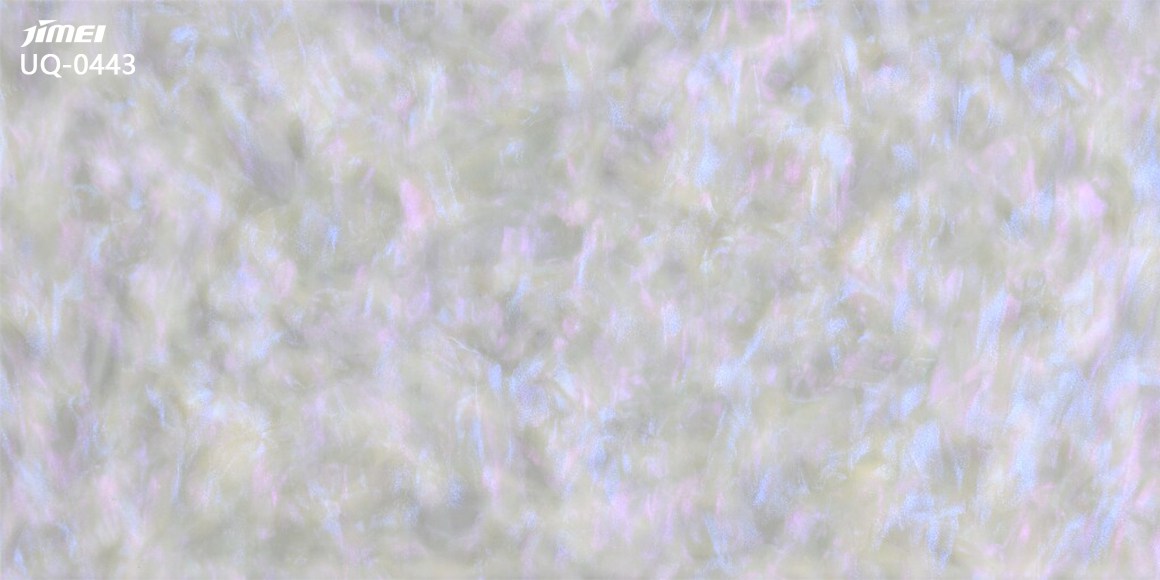

Finally, gradients generate smooth, gradual transitions by precisely exchanging different colors and textures during the extrusion process.